Research - Der Pharmacia Lettre ( 2021) Volume 13, Issue 8

Received: 22-Jul-2021

Published:

30-Aug-2021

, Citations: Parija, Swalin, Mohanta Guru Prasad, Nanda Upendra Nath, Saikishore V. In vitro and in vivo Evaluation of Natural Polymers Loaded Core-in-Cup Tablets of Budesonide for Potential Application in the Prophylaxis of Ulcerative Colitis. Der Pharm Lett 13 (2021) :153-161.

,

Copyright: © 2021 Swalin P, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

In the present study, an effort was made to develop the colon targeted drug delivery system of budesonide was designed with the intention of delivering the drug in the colon region for effective treatment of inflammatory bowel disease. Colon targeted core-in-cup tablets were prepared in two steps. Core tablets and cup tablets were prepared separately. The core tablets were kept in cup tablets and coated by using cellulose acetate phthalate as enteric coating polymers. The core-in-cup tablets were subjected to various evaluation techniques. In order to simulate the pH changes along the GI tract, three dissolution media with pH 1.2, 7.4 and 6.8 were sequentially used. FTIR study confirmed that there was no interaction between drug and polymer. The physicochemical parameters of all the formulations were found to be in compliance with the pharmacopoeial standards. The results confirmed that the tablets coated with 10% w/w cellulose acetate phthalate showed a lag time of 5 hr corresponds to time required to reach colonic region. Among all the formulations Budesonide tablets prepared with Moringa olifera gum in 1:1.5 ratios shown sustained drug release for a period of 12 hours. The correlation coefficient values of dissolution kinetics data clearly indicated that the drug release followed zero order kinetics and the mechanism of drug release was governed by peppas-korsmeyer model. The obtained results revealed the capability of the system in delaying drug release for a programmable period of time and for effective treatment of inflammatory bowel disease in the colon region

Budenoside, Biodegradable gums, Eudragit, film coat.

Ulcerative Colitis (UC) is an idiopathic inflammatory bowel disease, commonly occurring in developed countries in individuals aged between 15 and 30 years with an additional peak in the sixth decade of life. Despite improved understanding of the mechanisms of intestinal inflammation, the etiology and pathogenesis of inflammatory bowel disease remain obscure [1]. Budesonide is a second generation glucocorticoid exhibits high affinity to the corticosteroid receptors by decreasing the production of cytokines and interleukins [2]. Budesonide have half-life of 2-4 h with an oral bioavailibility of 10%. Budesonide is used in the pharmacotherapy of inflammatory bowel disease, especially in the treatment of ulcerative colitis and Crohn’s disease [3]. Inflammatory bowel diseases can be treated more effectively if drugs are targeted to the colon. Colonic drug delivery is also useful for better systemic absorption of drugs because of less hostile environment prevailing in the colon compared to stomach and small intestine. In normal oral controlled release formulations, it was found that less than 5% of the drug was available beyond the ileum and cecum, and therefore, colonic delivery still needs to be optimized by a more reliable targeted system. Budesonide undergoes approximately 85% first pass metabolism [4].To overcome these drawbacks, the present study was undertaken to investigate the colon targeted drug delivery system of budesonide through core-in-cup tablet technique. Due to the distal location of the colon in the gastrointestinal tract, core-in-cup tablet should prevent drug release in the stomach and small intestine and produce a gradual onset of drug release upon entry into the colon [5]. Hence in the present study, Core-in-cup tablet of budesonide was designed with the intention of delivering the drug in the colon region for effective treatment of inflammatory bowel disease. Most of the strategies in time-dependent drug delivery are dependent on the principle to delay the drug release until approximate influx in the colon region. Although the relative consistency of transit times in the small intestine is because of the potentially large variation in gastric emptying time, the colon influx time cannot be exactly predicted. Therefore, by suppressing drug release in the stomach and thus reducing the effect of variations in gastric residence time, appropriate integration of pH-sensitive and time-dependent systems in a single dosage form should improve colon drug delivery. The release of water-soluble drug from a water-soluble polymeric platform is often rapid, and therefore hydrophobic polymer may be included within the matrix formulation to offer a greater control drug release [6]. Core-in-cup tablets have been developed by direct compression based on combination of hydrophobic polymers and a gelling hydrophilic polymer, microcrystalline cellulose, to achieve a 20-h sustained release formulation of Budenoside tablets using Cellulose acetate phthalate as coating polymer to produce a delivery system in which the release of drug is modulated. Cellulose acetate phthalate coat was employed to delay the penetration of dissolution medium into the matrix, thereby decreasing drug release rate [7]. Due to the distal location of the colon in the gastrointestinal tract, core and cup technique should prevent drug release in the stomach and small intestine and produce a gradual onset of drug release upon entry into the colon [8].

Budenoside was generously gifted by RPG Life Sciences Ltd. (Mumbai, India). All the chemicals utilized were of suitable analytical grade and used as and when required. Biodegradable-natural Gums were procured from Nutriroma Company at Hyderabad and all the chemicals required were purchased from national scientifics, Guntur.

Preparation of Budenoside core tablet

The controlled release matrix tablet of Budenoside was prepared by wet granulation method [9]. The required quantities of Budenoside, PVPK-30 (as a binder), Moringa olifera gum or Okra gum (as polymers) and lactose (as a diluent) were weighed as per formula given in Table 1 and these ingredients were mixed uniformly and prepared a wet mass by addition of binder solution. The wet mass was passed through sieve number #12 and allowed to drying for 30 minutes in a tray dryer for 60°C. The dried granules were passed through the sieve number #16 and finally lubricated with talc and magnesium stearate. The obtained dry granules were weighed into individual tablets and finally compressed into the tablet by 16 station rotary tablet compression machine using 9 mm flat punches. (RIMEK, Karnavati Engineering Ltd., Gujarat, India). The core tablets of AZA having an average weight of 300 ± 5 mg were prepared by direct compression. Different gums were used as binders cum hydrophilic matrix former, anhydrous lactose as diluents and magnesium stearate as lubricant, Talc as glidant [10]. Fifty core tablets and compression-coated tablets were prepared in duplicate Preparation of cup tablet: The cup formulations were formulated by direct compression technique. In which the required quantities of Eudragit RS100 and microcrystalline cellulose according to the formula shown in Table 2, were weighed and mixed uniformly and finally the powder mixture was compressed by 16 station rotary tablet compression machine by using special punch designed and fabricated, to prepare cup tablets. The newly designed upper 12 mm punch has protrusion and lower punch (12 mm) remains flat faced [11].

Evaluation of granules

Flow properties of the prepared granules were evaluated. Other properties of the granules evaluated were bulk density, true density apparent density, and porosity using standard reported methods, weight variation test was conducted as per specifications of IP hardness and friability of the tablets formulated were evaluated using a Monsanto hardness tester and a Roche friabilater, respectively [12].

Preparation of core in cup tablet

The cups were placed in a 12 mm die cavity and core tablet was inserted into the cups and compressed with 12 mm flat faced punches. The composition of the core in cup tablets was given in Table 3.

Enteric coating

Core in cup tablet were further coated with enteric coating polymer (cellulose acetate phthalate) by spray coating method. 9% cellulose acetate phthalate in 8:2 (v/v) mixture of acetone: Ethanol plasticized with dibutylphthalate (0.75%), was used as a coating solution. Talc (0.1% w/v) was added as anti-adherant and the solution was stirred for 15 min. Placed the core in cup tablets into a coating pan, the coating solution was sprayed over the tablets by R&D coater, rotating with a speed of 15 rpm, the pressure of the spray gun was maintained at 0.1 M.Pa and the air temperature was maintained at 35°C-40°C. The tablets were coated to a 5%, 7.5% and 10% w/w total weight gain [13].

Post compression evaluation of budenoside tablets

Weight variation: For estimating weight variation, 20 tablets of each formulation were weighed using an electronic balance (Denver Instrument, Gottingen, Germany) and the test was performed according to the official test [14].

Thickness: The thickness of the tablet was measured using a Digital Vernier Calliper (Mitutoya Digimatic Calliper, Kanagawa Japan). Hardness The crushing strength of ten tablets was measured using Monsanto tablet hardness tester (Interlabs, Ambala, India). A tablet hardness of about 5-7 kg/cm is considered adequate for mechanical stability.

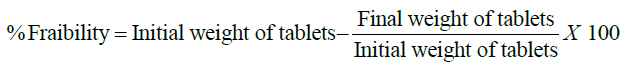

Friability: The friability of the tablets was determined in Roche Friabilator (Model 902, EI product, Panchkula, India). Ten tablets were weighed accurately from each batch of tablets and placed in the tumbling chamber and rotated at 25 rpm for a period of 4 min. Tablets were taken and again weighed. The percentage loss was determined by using the formula:

The results of Post compression parameters were reported in Table 5.

Estimation of drug content: The drug content in each formulation was determined by triturating 20 tablets and the drug equivalent to 50 mg was placed in 100 ml volumetric flask and final volume was made up to 100 ml with 6.8 pH phosphate buffer. Then the samples were taken with suitable dilutions and concentration of drug in the samples was measured by using U.V visible spectroscopy at 304 nm [15].

Determination of post compressional parameters of cup tablets

Depth of the cavity: Depth of the cavity of cup tablets was determined by using thread and scale [16].

Friability: The friability tests for cup tablets were determined by using Friabilator.

Thickness: The thickness of the cup tablets were determined by using Vernier calipers.

Evaluation studies of enteric coated Budenoside core in cup tablets

Disintegration test for enteric coated Budenoside core in cup tablets: Compendial in-vitro test methods for enteric coated tablets have traditionally relied on a two stage disintegration type test in order to confirm enteric performance. Six tablets were initially treated in tablet disintegration tester using 0.1 M Hcl for 2 hrs and then the tablets were subjected to further 3 hr in 7.4 Ph phosphate buffers [17].

Dissolution test for enteric coated Budenoside core in cup tablets: In-vitro dissolution studies of enteric coated core in cup tablets were possessed by using dissolution apparatus (USP II) paddle method.Enteric coated core in cup tablet formulations were selected based on dissolution studies for the core tablets. In order to simulate the pH changes along the GI tract, three dissolution media with pH 1.2, 7.4 and 6.8 were sequentially used referred to as sequential pH change method. When performing experiments, the pH 1.2 medium was first used for 2 hours (since the average gastric emptying time is 2 hrs.), then removed and the fresh pH 7.4 phosphate buffer saline (PBS) was added. After 3 hours (average small intestinal transit time is 3 hrs.), then the medium was removed and colonic fluid pH 6.8 buffer was added for subsequent hours. Nine hundred milliliters of the dissolution medium was used at each time. Rotation speed was 100 rpm and temperature was maintained at 37 ± 0.5°C. Enteric coated Budenoside core in cup tablets equivalent to 9 mg of Budenoside was used in each test. Five milliliters of dissolution media was withdrawn at predetermined time intervals and fresh dissolution media was replaced. The withdrawn samples were at 304 nm for Budenoside respectively, by UV absorption spectroscopy and the cumulative percentage release was calculated over the sampling times [18] (Figures 1-4).

In the present investigation controlled release formulations of core tablets for per-oral administration using natural gums in order to increase its biological half and to determine the influence of formulation and preparation variables on matrix tablets characteristics. The granules were characterized with respect to angle of repose, bulk density, tapped density, Carr's index, and Hausner ratio. The parameters for evaluation of granules are depicted in Table 4. The angle of repose of different formulation batches from F1 to F6 was found to be from 27.24 ± 0.08° to 28.39 ± 0.07°. The angle of repose was less than 30° for all the formulation batches of granules, indicating good flow behavior. Similarly, bulk density and tap density of all the formulation batches from F1 to F6 were found to be from 0.511 ± 0.012 to 0.540 ± 0.008 g/ml and from 0.610 ± 0.007 to 0.681 ± 0.008 g/ml, depicting good flow properties of the granules. The Carr's index of all formulation batches was in the acceptable range from 12.70 ± 0.14 to 14.97 ± 0.08. The Hausner ratio of all formulation batches from F1 to F6 was found to be from 1.14 ± 0.09 to 1.17 ± 0.05. The Hausner ratio less than 1.25 indicates good flow ability.

The weight of each tablet was determined to be within the range of 200 ± 5 mg in order to maintain the relatively constant volume and surface area. All the formulated preparations were subjected to weight variation, hardness, friability and drug content. All tablets complied I. P. weight variation test requirement. The hardness was found to be in between 4-5 kg. The tablets satisfied USP friability requirement, as the % friability values are less than 1%. The percent drug content was found to be within 98%-102% of the labeled amount and hence compiled drug content requirement. The core tablet was successfully coated by coating technique and further core-in-cup tablet was coated with varying proportion of Cellulose acetate phthalate. The results of the in vitro dissolution studies of different batches of coated tablets indicated that increase in concentration of Cellulose acetate phthalate from 5% to 7.5% w/w and 10% w/w and keeping constant weight gain in thickness of polymers at 10% w/w, the lag time (the time required for drug release in SCF) was significantly increased to 5 h. The lag time was determined by separately running dissolution studies of cellulose acetate phthalate coated (5% to 7.5% w/w and 10% w/w) tablets in SCF for 5 hours at minimum time intervals. The amount of cellulose acetate phthalate coat was the key factor for such lag time. Lower amount of Cellulose acetate phthalate coat shows shorter lag time, and higher amount shows longer lag time. Core-in-cup tablet with a coating level of 10% w/w showed a lag time of 5 hr corresponds to time required to reach colonic region. During dissolution studies, it was observed that, the enteric coated core in cup tablets was intact for 2 hrs in pH 1.2, and also in intestinal pH 7.4. With all the formulations, there was absolutely no drug release in pH 1.2 and also in intestinal pH 7.4., thus indicating the efficiency of 9% CAP for enteric coating.

From the in-vitro release studies of Core-in-cup tablet, it was observed that with all formulation, there was absolutely no drug release in simulated gastric fluid (acidic pH 1.2) for 2 hours and in simulated intestinal fluid (pH 7.4 phosphate buffer). But slow release was found in colonic medium (pH 6.8 phosphate buffer). In-vitro release profiles in colonic medium were found to have very good sustaining efficacy and shown in Figures 1 and 2. The tablets prepared with Moringa olifera gum in 1:0.5, 1:1 and 1:1.5 ratios shown sustained drug release for a period of 10 hours, 11 hours and 12 hours respectively and tablets prepared with Okra gum in 1:0.5, 1:1 and 1:1.5 ratios shown sustained drug release for a period of 9 hours, 10 hours and 11 hours respectively.

To ascertain the mechanism of drug release, the dissolution data was analyzed by zero order, first order, and Higuchi and peppas equations. When the amount of drug release values were plotted against time straight lines were obtained in all the cases indicating that the rate of drug release from these matrix tablets followed zero order kinetics. The plot of log % Drug Released vs. log time (peppas plots) was drawn. The plots were found to be linear with all matrix tablets. Release Kinetics of matrix tablets, the time required to get 50% drug release (T50) and 90% drug release (T90) was calculated and were shown in Table 8.The exponential coefficient (n) values were found to be in between 0.7199 to 0.7908, indicating that the drug release followed non fickian mechanism. These results indicated that the release rate was found to decrease with increase in concentration of natural polymer employed (Tables 1-8).

| Ingredients | F1 | F2 | F3 | F4 | F5 | F6 |

|---|---|---|---|---|---|---|

| Budesonide | 9 | 9 | 9 | 50 | 50 | 50 |

| Povidone | 10 | 10 | 10 | 10 | 10 | 10 |

| Moringa olifera gum | 25 | 50 | 75 | - | - | - |

| Okra gum | - | - | - | 25 | 50 | 75 |

| Lactose | 152 | 127 | 102 | 152 | 127 | 102 |

| Magnesiumstearate | 2 | 2 | 2 | 2 | 2 | 2 |

| Talc | 2 | 2 | 2 | 2 | 2 | 2 |

| Total | 200 | 200 | 200 | 200 | 200 | 200 |

| Ingredients | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| Eudragit RS100 | 400 | 400 | 400 | 400 | 400 | 400 |

| MCC | 42 | 42 | 42 | 42 | 42 | 42 |

| Mg. stearate | 4 | 4 | 4 | 4 | 4 | 4 |

| Talc | 4 | 4 | 4 | 4 | 4 | 4 |

| Total | 450 | 450 | 450 | 450 | 450 | 450 |

S. No. |

Core in cup formulations |

Combination of core and cup formulations |

|---|---|---|

| 1 | BCC1 | F1 (core)+C1 (cup) |

| 2 | BCC2 | F1 (core)+C2 (cup) |

| 3 | BCC3 | F1 (core)+C3 (cup) |

| 4 | BCC4 | F1 (core)+C4 (cup) |

| 5 | BCC5 | F1 (core)+C5 (cup) |

| 6 | BCC6 | F1 (core)+C6 (cup) |

| Formulation | Evaluation parameters | ||||

|---|---|---|---|---|---|

| Bulk density (g/ml) | Tapped density (g/ml) | Compressibility index (%) | Hausner’s ratio | Angle of repose (θ) | |

| F1 | 0.520 ± 0.011 | 0.620 ± 0.014 | 13.88 ± 0.23 | 1.16 ± 0.01 | 27.31 ± 0.12 |

| F2 | 0.531 ± 0.013 | 0.681 ± 0.008 | 13.91 ± 0.31 | 1.16 ± 0.01 | 29.18 ± 0.14 |

| F3 | 0.570 ± 0.009 | 0.660 ± 0.011 | 12.70 ± 0.14 | 1.14 ± 0.02 | 25.14 ± 0.16 |

| F4 | 0.529 ± 0.010 | 0.630 ± 0.009 | 14.97 ± 0.08 | 1.17 ± 0.09 | 28.06 ± 0.11 |

| F5 | 0.540 ± 0.008 | 0.620 ± 0.012 | 13.94 ± 0.13 | 1.14 ± 0.06 | 27.24 ± 0.08 |

| F6 | 0.511 ± 0.012 | 0.610 ± 0.007 | 14.85 ± 0.15 | 1.17 ± 0.05 | 28.39 ± 0.07 |

| Formulation | Parameters | ||||

|---|---|---|---|---|---|

| Weight variation (mg) | Hardness (kg/cm2) | Friability (%) | Drug content (%) | Thickness (mm) | |

| F1 | 200 ± 1.4 | 4.2 ± 0.03 | 0.22 | 99.13 | 2.95 ± 0.03 |

| F2 | 200 ± 1.3 | 4.4 ± 0.02 | 0.36 | 99.36 | 2.93 ± 0.02 |

| F3 | 200 ± 1.2 | 4.5 ± 0.05 | 0.47 | 99.28 | 2.98 ± 0.01 |

| F4 | 200 ± 1.4 | 4.2 ± 0.02 | 0.39 | 99.53 | 2.95 ± 0.03 |

| F5 | 200 ± 1.6 | 4.3 ± 0.03 | 0.43 | 99.32 | 2.96 ± 0.02 |

| F6 | 200 ± 1.5 | 4.4 ± 0.05 | 0.52 | 99.48 | 2.98 ± 0.03 |

| S. No. | Post-compressional parameters | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|---|

| 1 | Depth of the cavity (mm) | 3.1 ± 0.02 | 3.1 ± 0.12 | 3.1 ± 005 | 3.1 ± 0.03 | 3.1 ± 0.09 | 3.1 ± 0.05 |

| 2 | Friability (%) | 0.47 | 0.42 | 0.39 | 0.52 | 0.44 | 0.33 |

| 3 | Thickness (mm) | 4.52 | 4.68 | 4.71 | 4.73 | 4.66 | 4.67 |

| S. No. | Disintegration signs | BCC1 | BCC2 | BCC3 | BCC4 | BCC5 | BCC6 |

|---|---|---|---|---|---|---|---|

| 1 | 1st hour | No sign | No sign | No sign | No sign | No sign | No sign |

| 2 | 2nd hour | No sign | No sign | No sign | No sign | No sign | No sign |

| 3 | 3rd hour | No sign | No sign | No sign | No sign | No sign | No sign |

| 4 | 4th hour | No sign | No sign | No sign | No sign | No sign | No sign |

| 5 | 5th hour | No sign | No sign | No sign | No sign | No sign | No sign |

| Formulation | Correlation coefficient value | Release rate constant (mg/hr)k0 |

Exponential coefficient (n) | T50 (hr) |

T90 (hr) |

|||

|---|---|---|---|---|---|---|---|---|

| Zero order | First order | Matrix | Peppas | |||||

| BCC1 | 0.9918 | 0.8208 | 0.9518 | 0.9961 | 0.918 | 0.7199 | 4.9 | 8.8 |

| BCC2 | 0.9951 | 0.8098 | 0.9444 | 0.9964 | 0.818 | 0.7605 | 5.5 | 9.9 |

| BCC3 | 0.9986 | 0.7925 | 0.9354 | 0.9995 | 0.762 | 0.7908 | 5.9 | 10.6 |

| BCC4 | 0.9984 | 0.7672 | 0.9586 | 0.9786 | 1.063 | 0.7385 | 4.23 | 7.5 |

| BCC5 | 0.9896 | 0.8434 | 0.9570 | 0.9972 | 0.930 | 0.7508 | 4.8 | 8.6 |

| BCC6 | 0.9933 | 0.7522 | 0.9501 | 0.9970 | 0.848 | 0.7643 | 5.3 | 9.6 |

It is concluded from the present study that appropriate combination of a pH-dependent polymer (Eudragit RS100) with a overcoat of Cellulose acetate phthalate was suitable for adequately sustained drug release and to protect Budenoside from being released in the upper region of the GI system. The in vitro drug release studies indicate that the optimized formulation was a promising system targeting Budenoside to the colon. The drug release pattern from all formulations was best fitted Korsmeyer-Peppas equation with non-Fickian diffusion kinetics. Tablet with a coating level of 10% w/w showed a lag time of 5 hr corresponds to time required to reach colonic region.The coating polymers exhibited good results in targeting the colonic study. Formulations F3 was found to be more efficient controlled release in delivering the drug Budenoside to the colonic site analyzed with respect to dissolution release studies. The obtained results showed the capability of the system in delaying drug release for a programmable period of time and the possibility of exploiting such delay to attain colon targeting.

I express deep gratitude, Sincere and heartful thanks to my research guide, co-guide who have provided excellent guidance, knowledge on the subjects and regular observation.It is my pleasure to express my deep sense of gratitude and thankfulness to RPG Life Sciences Ltd,Mumbai, Nutriroma Company, Hyderabad, National Scientifics, Guntur, Spira labs, Hyderabad and research lab of Institute of Pharmacy & Technology Salipur,Cuttack,Odisha for their constant and valuable support.

Citation: Parija, Swalin, Mohanta Guru Prasad, Nanda Upendra Nath, Saikishore V. In vitro and in vivo Evaluation of Natural Polymers Loaded Core-in-Cup Tablets of Budesonide for Potential Application in the Prophylaxis of Ulcerative Colitis. Der Pharm Lett 13 (2021) :153-161.

Copyright: © 2021 Swalin P, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.